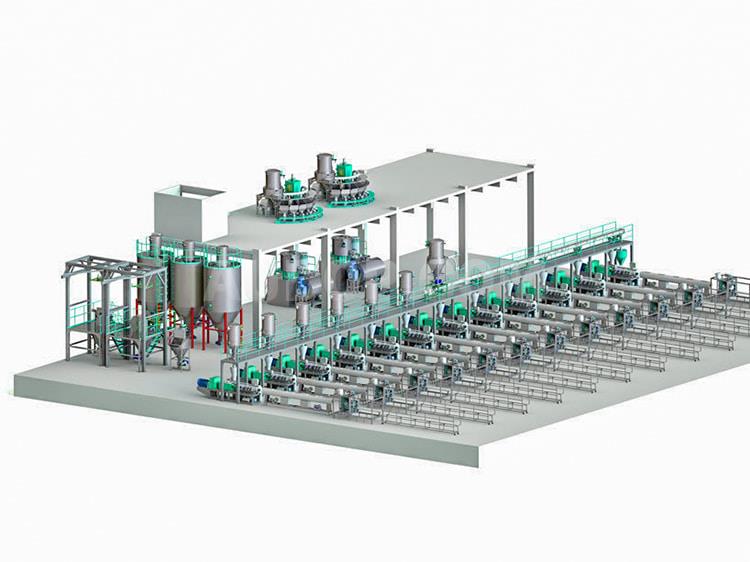

PVC Fully Automatic Material Blending System

1. High-Precision Dynamic Measurement:

Equipped with curved beam pressure sensors and anti-stick coated screws, our system offers unparalleled high-precision metering. It supports individual weighing of main and auxiliary materials with secondary adjustments, eliminating manual errors and accommodating complex formulations.

2. Efficient Mixing Technology:

Combining high-speed hot mixers with horizontal cold mixers, our system precisely regulates temperature and rotational speed, enhancing material uniformity and thermal energy utilization. This ensures smooth, continuous production tailored to the needs of global manufacturers.

3. Smart Conveying System:

Our intelligent conveyance system supports negative/positive pressure pneumatic conveyance, tube chain conveyance, and screw conveyance. Compatible with bulk and ton bag materials, its fully enclosed design minimizes dust spillage. This system adapts to various process needs, reducing labor costs and enhancing workshop environments.

4. Eco-Friendly Dust Control:

Our eco-friendly dust removal design utilizes high-performance filter cartridges and pulse jet cleaning systems, offering high dust collection efficiency and preventing secondary pollution.

5. Modular Flexibility:

Our modular design allows for customization with stainless steel silos or PVC hose components based on factory layouts. These corrosion-resistant components accommodate various feeding modes, including ton bags and small-ratio formulas, ensuring versatility across diverse production scenarios.

6. Intelligent Monitoring:

Advanced intelligent monitoring and management features enable real-time tracking, dynamic adjustments, fault alerts, and production data analytics, ensuring continuous and stable operation tailored to the needs of manufacturers.

Overview

The PVC Fully Automatic Material Blending System is an intelligent, cutting-edge solution for PVC product manufacturing lines, integrating material collection, high-precision metering, efficient mixing, eco-friendly conveyance, and advanced intelligent monitoring. It's designed to meet the demands of global manufacturers seeking precision and efficiency.Leveraging PLC control in synergy with industrial PC technology, our system supports multi-formula storage and dynamic adjustments, ideal for large-scale production of PVC pipes, sheets, profiles, and pellets. Customized solutions cater to annual capacities ranging from 2,000 to 100,000 tons, meeting the diverse needs of manufacturers.Our system features fully enclosed conveyance, high-efficiency dust removal, and modular design, empowering clients to achieve automation upgrades, compliant dust control, and cost reduction. This modular approach ensures operational efficiency and environmental compliance.

Product Composition

• Material Collection System: Bulk bag unpacking stations and pneumatic conveying devices for efficient raw material intake.

• Weighing & Batching System: Independent main/auxiliary material bins with secondary fine-tuning for high dynamic accuracy, ideal for small-ratio additives (e.g., colorants).

• Mixing Unit: High-speed hot mixer and horizontal cold mixer with automated temperature and parameter control for consistent material quality.

• Conveying System: Vacuum loaders, screw conveyors, and tubular chain conveyors to integrate with extruders, pelletizers, and downstream equipment.

• Dust Control & Automation: Balanced dust removal units, integrated control cabinets, and HMI interfaces with remote diagnostics and cloud-based data management.

• Auxiliary equipment: Stainless steel raw material hoppers, operating platforms, screening equipment and switching valves ensure long - term stable operation of the system.

Suitable Materials/Industries

Materials: PVC powder, pellets, color masterbatches, plasticizers, and other corrosive raw materials requiring precise ratios.

Industries: PVC pipe, sheet, profile, and pellet production lines; plastic pelletizing, pharmaceutical packaging, electronic component encapsulation, and chemical manufacturing.

Scenarios: Large - scale factories, customers needing dust control, diverse recipes and automation upgrading.

After-Sales Service

We provide comprehensive after-sales services for our PVC Fully Automatic Material Blending System, including equipment installation and debugging, operator training, regular maintenance, and troubleshooting. Our professional team ensures seamless operation, promptly addressing any issues encountered by clients. Additionally, we offer retrofitting services for older systems to meet increasingly stringent dust control and new process control requirements, ensuring continued operational excellence.